Sapphire Optical Windows

Uncoated sapphire has excellent surface hardness, and the range of transmittance extends from ultraviolet to mid-infrared wavelength region. Sapphire can only be scratched by a few substances other than it. The uncoated substrate is chemically inert and insoluble in water, common acids or alkalis at temperatures up to about 1000°C. Our sapphire window is a z-axis section, so the c-axis of the crystal is parallel to the optical axis, eliminating the birefringence effect of transmitted light.

Specification

Dimension Tolerance: 0.0/-0.1mm

Thickness Tolerance: ±0.1mm

Clear Aperture: ≥90%

Surface Quality: 40/20(Dimension≤50.8mm) 60/40(Dimension>50.8mm)

Flatness: λ/4@633nm

Parallelism: ≤1′

Chamfer: 0.2×45°

Sapphire Protective Windows

Sapphire protective window sheet (protective window) is a special window sheet processed by using the physical and chemical properties of sapphire, which is used to protect the internal instrument or container seal in a specific environment (high temperature environment, pressure environment, corrosive environment, etc.) to effectively isolate the environment and observers.

Sapphire protection windows can be divided into the following types according to the use environment:

● Withstand voltage protection window

● High temperature protection window

● Deep water protection window

● Chemical corrosion protection window

Sapphire protective window is generally used in underwater detection, high temperature scene, oilfield exploration, pressure vessel, chemical site and high-power laser operation protection.

Shape Forming Method

CNC or laser

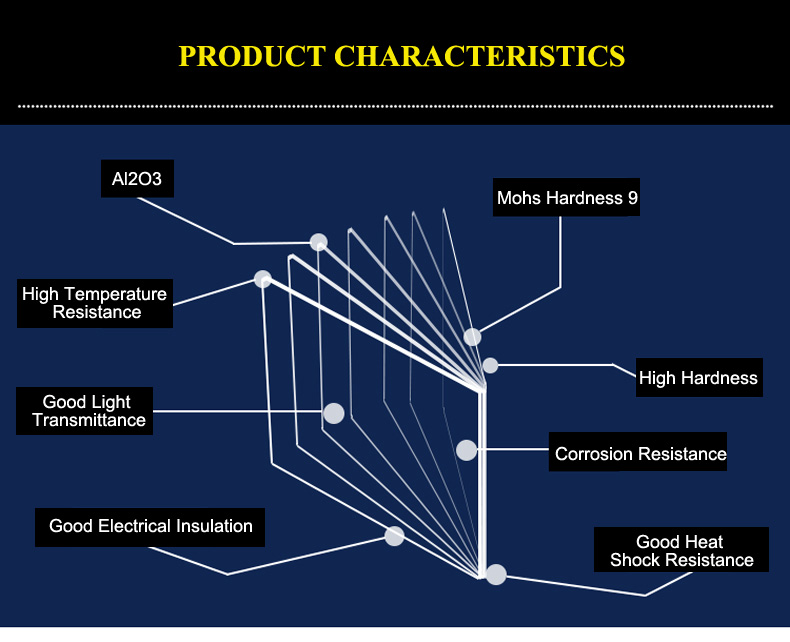

Product Characteristics

Material Properties

Sapphire is a single crystal aluminum oxide (Al2O3). It is one of the hardest materials. Sapphire has good transmission characteristics over the visible, and near IR spectrum. It exhibits high mechanical strength, chemical resistance, thermal conductivity and thermal stability. It is often used as window materials in specific field such as space technology where scratch or high temperature resistance is required.

| Molecular Formula | Al2O3 |

| Density | 3.95-4.1 g/cm3 |

| Crystal Structure | Hexagonal Lattice |

| Crystal Structure | a =4.758Å , c =12.991Å |

| Number of molecules in unit cell | 2 |

| Mohs Hardness | 9 |

| Melting point | 2050 ℃ |

| Boiling Point | 3500 ℃ |

| Thermal Expansion | 5.8×10-6 /K |

| Specific Heat | 0.418 W.s/g/k |

| Thermal Conductivity | 25.12 W/m/k (@ 100℃) |

| Refractive Index | no =1.768 ne =1.760 |

| dn/dt | 13x10 -6 /K(@633nm) |

| Transmittance | T≈80% (0.3~5μm) |

| Dielectric Constant | 11.5(∥c), 9.3(⊥c) |

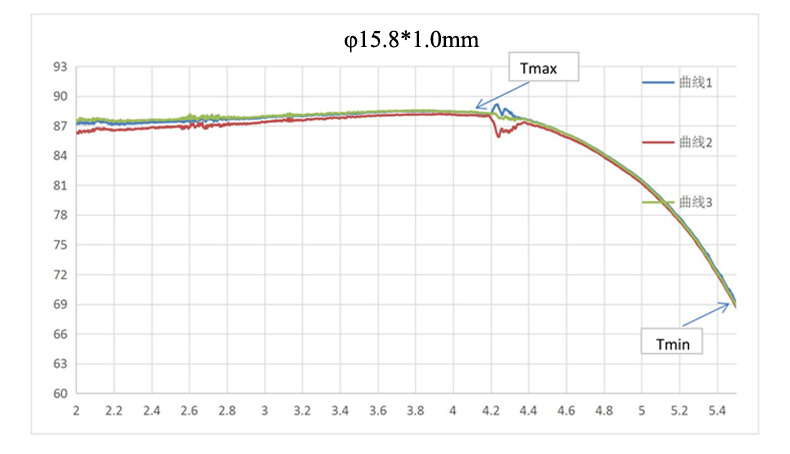

Transmission Curve of Sapphire Optical Window

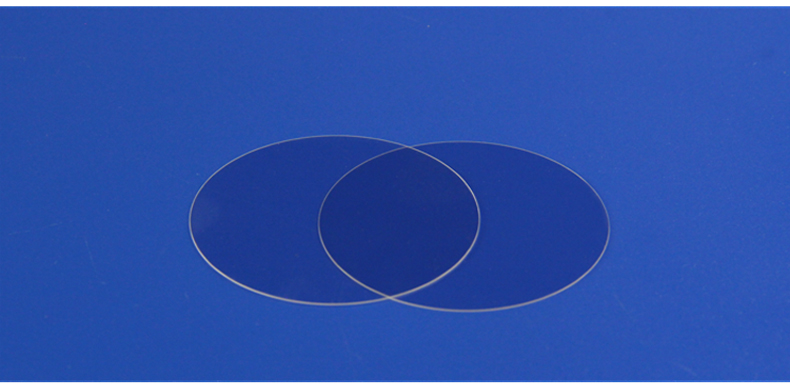

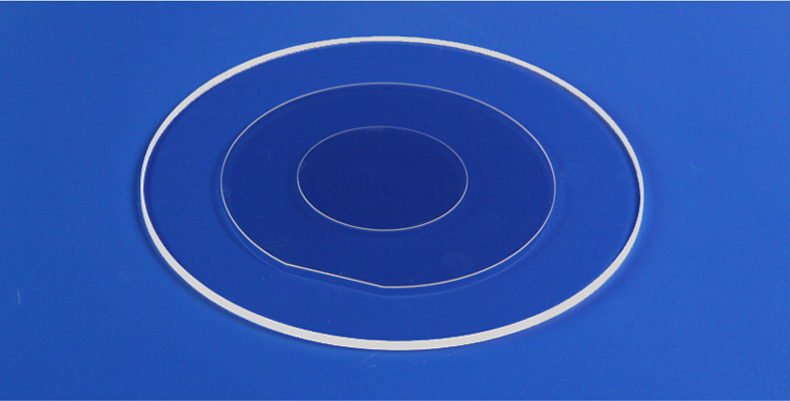

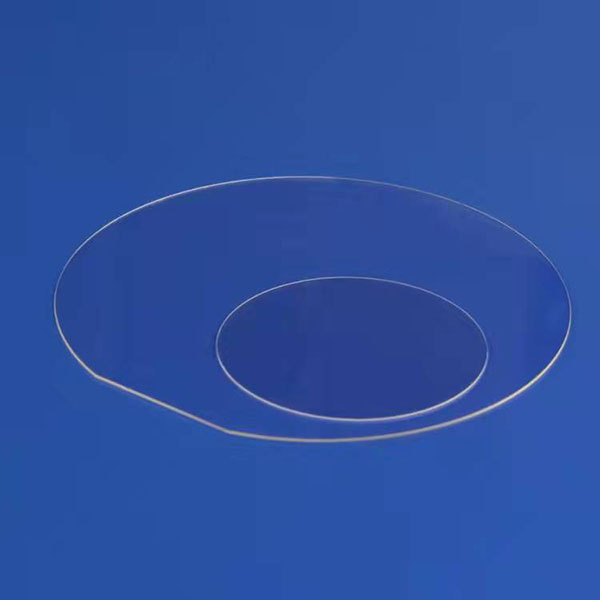

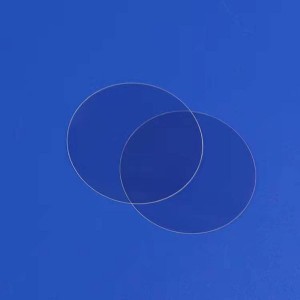

Product Show