OEM Manufacturer Frosted Quartz Plate - Customizable Precision Fused Quartz Glass Machining – LZY

OEM Manufacturer Frosted Quartz Plate - Customizable Precision Fused Quartz Glass Machining – LZY Detail:

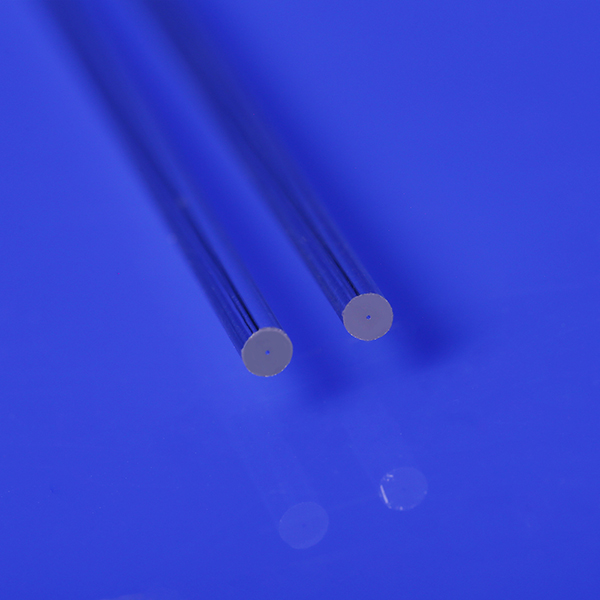

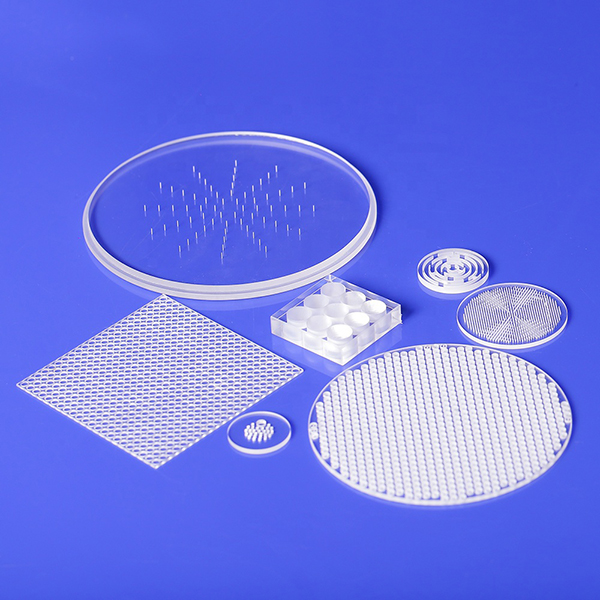

The High Precision of CNC Machined can supply Grooved Quartz Sheet, such as slotting, drilling, and beveling. The advantage is that the processing accuracy is high and it can meet the needs of different customers.

Material

Fused quartz glass

UV Fused silica

Borosilicate 3.3

Schott borofloat 33 glass

Corning® 7980

Sapphire

Tempered glass

B270 Glass

K9 glass

Factors affecting price

As a manufacturer with rich processing experience, we will think from the perspective of customers and strive to provide suitable products.

Maybe our price is not the best, but our products must be your safe choice.

The following will have an impact on the quotation.

Raw materials: Quartz glass is divided into ultraviolet quartz (JGS1), far ultraviolet quartz (JGS2) and infrared quartz (JGS3). Choose the appropriate material according to your requirements.

Dimensions: the size of the external dimensions, thickness, surface accuracy, parallelism, these information are determined according to the purpose you use, The higher the accuracy requirement, the more expensive the price.

Quantity: The price of 2 pieces and 50 pieces, 500 pieces and 1000 pieces are different.

The complexity of the production, whether it is coated or not, the air line transmittance requirements of bubbles, and other special needs of customers will also affect the price.

Products shown

Applications

Military industrial complex

Machinery

Metallurgy

Optical instruments

High temperature sight glasses

Fire hole industries such as high temperature and other industries

Quartz Characteristic

| SIO2 | 99.99% |

| Density | 2.2(g/cm3) |

| Degree of the hardness mosh’ scale | 6.6 |

| Melting point | 1732℃ |

| Working temperature | 1100℃ |

| Max temperature can reach in a short time | 1450℃ |

| Acid tolerance | 30 times than ceramic,150 times than stainless |

| Visible light transmittance | Above 93% |

| UV spectral region transmittance | 80% |

| Resistance value | 10000 times than ordinary glass |

| Annealing point | 1180℃ |

| Softening point | 1630℃ |

| Strain point | 1100℃ |

If you’re looking for Machined quartz discs and Machined quartz plates suppliers who can deliver customized and high-quality Machined quartz plates, contact US.

Product detail pictures:

Related Product Guide:

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for OEM Manufacturer Frosted Quartz Plate - Customizable Precision Fused Quartz Glass Machining – LZY , The product will supply to all over the world, such as: Mongolia, Mombasa, Colombia, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.