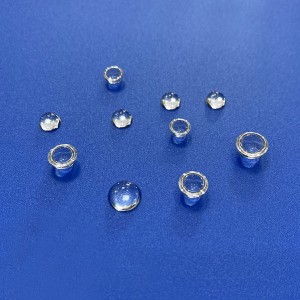

Factory Customized Precision Machining Sapphire

Sapphire has a hardness of Mohs 9, second only to diamond, and has good wear resistance. At the same time, it has excellent chemical stability and can resist the corrosion of almost any acid and alkali substances. In addition, the maximum temperature resistance of sapphire is 2060 ℃. Because of the above advantages of sapphire, sapphire is used in instruments and equipment, which can significantly improve the service life and withstand various harsh environments.

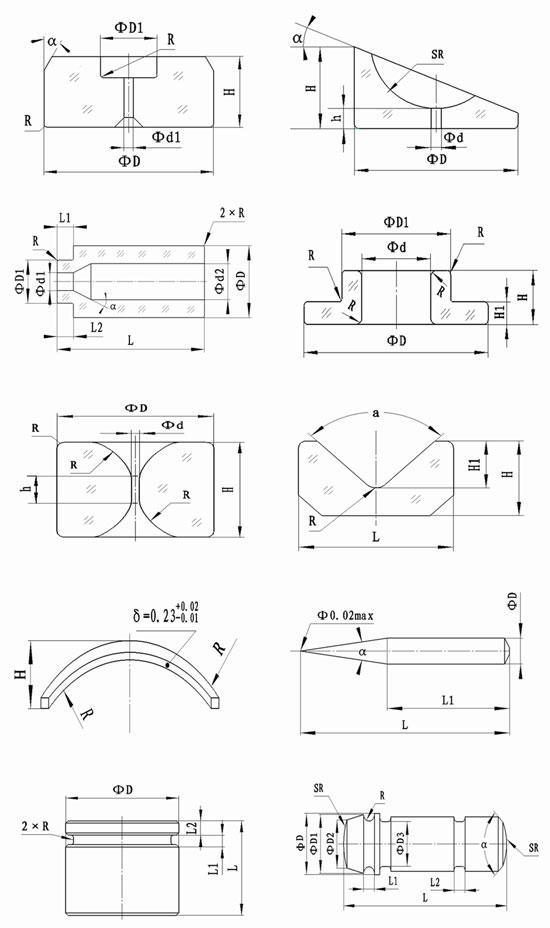

Sapphire precision parts often have complex shape requirements and precise sealing requirements. We can customize various shapes according to customers' drawings. We have precision cutting, grinding, polishing and testing equipment to ensure that each product meets the stringent requirements of customers.

Main Forming Methods

Material Properties

Sapphire is a single crystal aluminum oxide (Al2O3). It is one of the hardest materials. Sapphire has good transmission characteristics over the visible, and near IR spectrum. It exhibits high mechanical strength, chemical resistance, thermal conductivity and thermal stability. It is often used as window materials in specific field such as space technology where scratch or high temperature resistance is required.

| Molecular Formula | Al2O3 |

| Density | 3.95-4.1 g/cm3 |

| Crystal Structure | Hexagonal Lattice |

| Crystal Structure | a =4.758Å , c =12.991Å |

| Number of molecules in unit cell | 2 |

| Mohs Hardness | 9 |

| Melting point | 2050 ℃ |

| Boiling Point | 3500 ℃ |

| Thermal Expansion | 5.8×10-6 /K |

| Specific Heat | 0.418 W.s/g/k |

| Thermal Conductivity | 25.12 W/m/k (@ 100℃) |

| Refractive Index | no =1.768 ne =1.760 |

| dn/dt | 13x10 -6 /K(@633nm) |

| Transmittance | T≈80% (0.3~5μm) |

| Dielectric Constant | 11.5(∥c), 9.3(⊥c) |

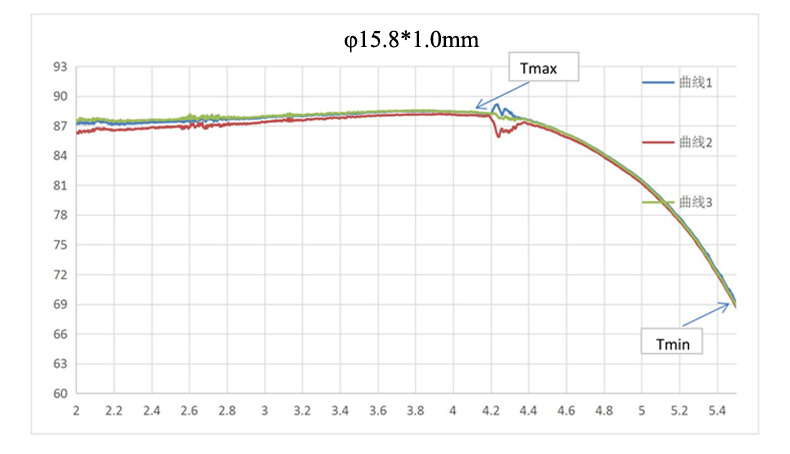

Transmission Curve of Sapphire Optical Window